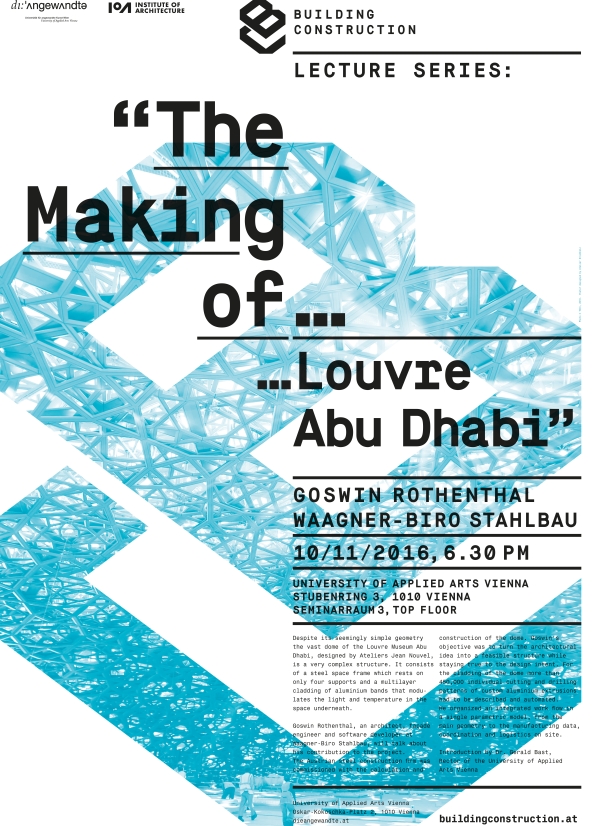

The Making of: Louvre Abu Dhabi

Architects: Ateliers Jean Nouvel

Die neue Vortragsreihe "Making of" der Angewandten. Einfüherende Worte Gerald Bast, Rektor Universität

für angewandte Kunst Wien

This is a new lecture series that delves into the planning and construction

processes of outstanding architecture and looks at the topic from a technical point of view.

It provides a forum for

experts who are – often little-noticed by the architecture discourse – working behind the scenes but play a key role for the

implementation of innovative architecture.

While the _making _of cinema blockbusters is well established as a film

genre of its own, one hardly learns anything about the genesis of great buildings. Usually in lectures about architecture

only the beginning and the end of the design and construction processes are presented: the key design ideas and the completed,

impeccably photographed building. In the lecture series _The Making of _special attention is being paid to the intermediate

process. It addresses the challenges of architecture production, trials and errors, research and technical progress.

The series will cover two lectures per semester on average.

Vortrag The Making of Louvre Abu Dhabi

Architects: Ateliers Jean Nouvel

Despite its seemingly simple geometry the vast dome of the Louvre Museum

Abu Dhabi is a very complex structure. It consists of a steel space frame which rests on only four supports and thus creates

the impression of hovering weightlessly above some irregularly arranged white cubes. A multilayer cladding of aluminium bands

masks the dome’s steel structure and modulates the light and temperature conditions of the space underneath. Jean Nouvel’s

purpose was to create a ‘rain of light’ as he called it, reminiscent of Mashrabiya and the specific atmosphere of Arabian

souks. Büro Happold developed the structural concept of the steel space frame, the Austrian steel construction firm Waagner-Biro

Stahlbau AG was commissioned with the calculation and construction of the steel dome.

GOSWIN ROTHENTHAL, an architect,

façade engineer and software developer at Waagner-Biro will talk about his contribution to the project. After having worked

on extraordinary architecture at Zaha Hadid for six years he wanted to know how a specialist contractor actually deals with

complex projects, so he joined Waagner-Biro Stahlbau. His objective was to turn the architectural idea into a feasible structure

while staying true to the design intent. For the cladding of the dome more than

450,000 individual cutting and drilling

patterns of custom aluminum extrusions had to be described and automated. He organized an integrated work flow in a single

parametric model, from the main geometry to the manufacturing data, coordination and logistics on site.